Page 1904 - S.I.T.E.切削工具ガイドブックVol.4 鉄鋼・難削材料用

P. 1904

Χ

ỽ

λ ӫࣷ

ồ

$655&34

53- 1

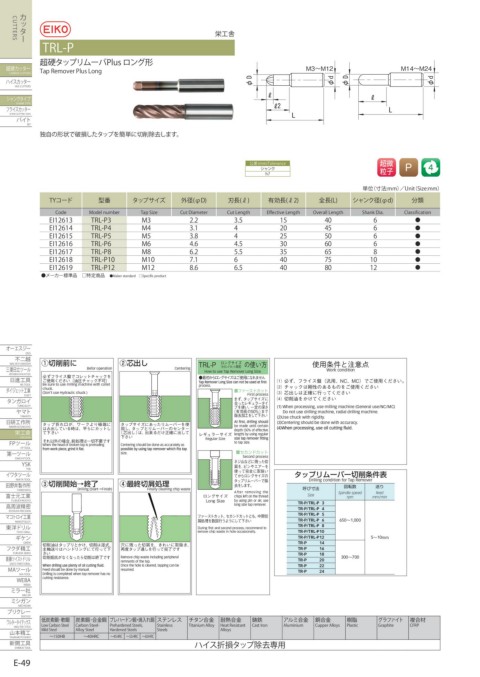

ߗλοϓϦϜʔό1MVT ϩϯάܗ

ߗΧολʔ 5BQ 3FNPWFS 1MVT -POH . ʙ. . ʙ.

$"3#*%& $655&34

' G ' G

ϋΠεΧολʔ ɹ

)44 $655&34

γϟϯΫλΠϓ

4)"/, 5:1&

ϑϥΠεΧολʔ

4$3&8 4-055*/( 4"84

όΠτ

#*5

ಠࣗͷܗঢ়Ͱഁଛͨ͠λοϓΛ؆୯ʹআڈ͠·͢ɻ

ެࠩ NN 5PMFSBODF

γϟϯΫ

I

୯Ґʢੇ๏ NNʣʗ6OJUʢ4J[F NNʣ

5:ίʔυ ܕ൪ λοϓαΠζ ֎ܘ П% ਕ Ὑ ༗ޮ Ὑ શ - γϟϯΫܘ ПE ྨ

$PEF .PEFM OVNCFS 5BQ 4J[F $VU %JBNFUFS $VU -FOHUI &GGFDUJWF -FOHUI 0WFSBMM -FOHUI 4IBOL %JB $MBTTJGJDBUJPO

&* 53- 1 . ˔

&* 53- 1 . ˔

&* 53- 1 . ˔

&* 53- 1 . ˔

&* 53- 1 . ˔

&* 53- 1 . ˔

&* 53- 1 . ˔

˔ϝʔΧʔඪ४ɹ˘ಛఆɹ˔.BLFS TUBOEBSEɹ˘4QFDJGJD QSPEVDU

ΦʔΤεδʔ

04(

ෆೋӽ

ϩϯάαΠζ

/"$)* '6+*,04)* ᶃલʹ ᶄਊग़͠ 53- 1 ʢηΧϯυΧοτઐ༻ʣ ͷ͍ํ ༻݅ͱҙ

ࡾඛཱπʔϧ Befor operation Centering How to use Tap Remover Long Size. Work condition

.*546#*4)* )*5"$)* 500- ඞͣϑϥΠε൫ͰίϨοτνϟοΫΛ ˔ ࠷ॳ͔ΒϩϯάαΠζ͝༻ʹͳΕ·ͤΜ

ਐ۩ ͝༻͍ͩ͘͞ʢ༉ѹνϟοΫෆՄʣ ᾇඞͣɺϑϥΠε൫ʢ൚༻ɺ/$ɺ.$ʣͰ͝༻͍ͩ͘͞ɻ

/4 500- Be sure to use milling machine with collet process. ᾈνϟοΫ߶ੑͷ͋ΔͷΛ͝༻͍ͩ͘͞

μΠδΣοτۀ chuck. ˙ϑΝʔετΧοτ ᾉਊग़͠ਖ਼֬ʹߦ͍ͬͯͩ͘͞

(Don't use Hydraulic chuck.)

%*+&5 First process

λϯΨϩΠ ·ͣɺλοϓαΠζʹ ᾊ༉Λ͔͚͍ͯͩ͘͞

߹ͬͨϨΪϡϥʔλΠ

56/("-0: ϓΛ͍ɺҰఆͷਂ͞ (1) When processing, use milling machine (General use/NC/MC)

ϠϚτ ʢ༗ޮͷ ʣ·Ͱ Do not use drilling machine, radial drilling machine.

:"."50 আڈՃΛͯ͠Լ͍͞ (2)Use chuck with rigidity.

ݚ࡞ॴ λοϓંΕޱ͕ɺϫʔΫΑΓۃʹ λοϓαΠζʹ͋ͬͨϦϜʔόʔΛ (3)Centering should be done with accuracy.

/*,,&/ ,04",64)0 Έग़͍ͯ͠Δ࣌ɺฏΒʹΧοτ͠ ༻͠ɺλοϓͱϦϜʔόʔͷηϯλʔ be made until certain

ӫࣷ ͯԼ͍͞ ʢਊग़͠ʣɺग़དྷΔ͚ͩਖ਼֬ʹग़ͯ͠ ϨΪϡϥʔαΠζ depth (50% of effective

ӫࣷ

length) by using regular

&*,04)"

&*,04)" ͦΕҎ֎ͷ߹ɺલॲཧҰෆཁͰ͢ Լ͍͞ Regular Size

'1πʔϧ When the head of broken tap is protruding Centering should be done as accurately as to tap size.

'1 500-

ୈҰπʔϧ size. ˙ηΧϯυΧοτ

Second process

%"**$)* 500- ωδࢁͳͲʹͬͨ

:4, ۵ΛɺϐϯΤΞʔΛ

:4, ͬͯશʹऔআ͍

Πϫλπʔϧ ͔ͯΒϩϯάαΠζͷ λοϓϦϜʔόʔ݅ද

*8"5" 500- λοϓϦϜʔόʔͰআ Drilling condition for Tap Remover

ాҪ࡞ॴ ᶅ։࢝ˠऴྃ ᶆ࠷ऴ۵ॲཧ ڈΛ͠·͢ɻ ݺͼੇ๏ ճస ૹΓ

5"/0* .'( Drilling (StartˠFinish) Finally cleaning chip waste After removing the Spindle speed feed

࢜ݩۀ ϩϯάαΠζ chips left on the thread Size rpm mm min

'6+*(&/ ,0(:0 -POH 4J[F by using pin or air, use TR-P/TRL-P 3

ߴपਫ਼ີ long size tap remover. TR-P/TRL-P 4

,04)6)" 13&$*4*0/

ϚίτϩΠۀ ϑΝʔετΧοτɺηΧϯυΧοτͱɺதؒ TR-P/TRL-P 5 650ʙ1 000

TR-P/TRL-P 6

۵ॲཧΛճߦ͏Α͏ʹͯ͠Լ͍͞

.",050-0:

౦༸υϦϧ %VSJOH pSTU BOE TFDPOE QSPDFTT SFDPNNFOE UP TR-P/TRL-P 8

50:0 %3*-- SFNPWF DIJQ XBTUF JO IPMF PDDBTJPOBMMZ TR-P/TRL-P10

Ϊέϯ TR-P/TRL-P12 5ʙ10NN

(*,&/ ༉λοϓϦͱ͔͚ɺ࣪ࣜɺ ݀ʹͬͨ۵Λɺ͖Ε͍ʹऔআ͖ɺ TR-P 14

ϑΫμਫ਼ ओ࣠ૹΓϋϯυϦϯάʹͯߦͬͯԼ ࠶λοϓ௨͠ΛߦͬͯྃͰ͢ TR-P 16

'6,6%" 4&*,0 ͍͞ TR-P 18

ࡈ౻πΠετυϦϧ ߅͕ͳ͘ͳͬͨΒऴྃͰ͢ Remove chip waste including peripheral TR-P 20 300ʙ700

remnants of the tap.

4"*50 58*45 %3*-- Once the hole is cleared, tapping can be TR-P 22

."πʔϧ Feed should be done by manual. resumed. TR-P 24

." 500- Drilling is completed when tap remover has no

cutting resistance.

8&#"

8&#"

ϛϥʔࣾ

.*--&3

ϛγΨϯ

.*$)*("/

ϒϦΫϨʔ

#-*$,-&

ϫϧλʔλΠςοΫε ૉ߯ŋೈ߯ ૉ߯ŋ߹ۚ߯ ϓϨϋʔυϯ߯ɾমೖΕ߯ εςϯϨε νλϯ߹ۚ ߹ۚ ரమ Ξϧϛ߹ۚ ಔ߹ۚ थࢷ άϥϑΝΠτ ෳ߹ࡐ

8"-5&3 5*5&9 -PX $BSCPO 4UFFM $BSCPO 4UFFM 1SFIBSEFOFE 4UFFMT 4UBJOMFTT 5JUBOJVN "MMPZ )FBU 3FTJTUBOU $BTU *SPO "MVNJOJVN $VQQFS "MMPZT 1MBTUJD (SBQIJUF $'31

ࢁຊਫ਼ .JME 4UFFM "MMPZ 4UFFM )BSEFOFE 4UFFMT 4UFFMT "MMPZT

:".".050 4&*,0 ʙ )# ʙ )3$ ʙ )3$ ʙ )3$ ʙ )3$

৽։۩ ϋΠεંଛλοϓআڈઐ༻

4)*/,"* 500-

E-49